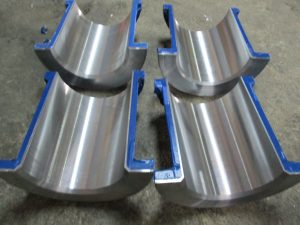

WIRE ARC SPRAY

Temperature on the work piece white being sprayed is less than 100 C°. Spraying Materials could be different from the original material in order to creating new properties on the surface of the work piece: for example: we can choose variety of materials having hardness varying between 25-65 HRC to increase the hardness of the work piece for wear and abrasive protection. Spraying thickness could be achieved from 0.1 mm. to more than 5.0 mm. 24 Hour workshop and on-site Service.

SPRAY AND FUSE

Using Nickel Alloy or Tungsten Carbide powder for Wear and Abrasive protection, Hardness increasing staring from 25-70 HRC, Working temperature of the sprayed work piece could be up to 1200 C°

THERMAL SPRAY ALUMINIUM

Thermal Spray is the procedure for metallized aluminium or zinc coating ro protect steel from oxidizing at 450 °C to 620°C in the presence of wire arc spray such as pure aluminium wire, pure zinc wire and etc.

We can apply thermal spray to small job in workshop like maintenance service up to huge project (on-site service) such as flare tower structure, pressure vessel, inner tank of electrical transformer, boiler tube and etc.

THERMAL SPRAY ZINC

Thermal Spray is the procedure for metallized aluminium or zinc coating ro protect steel from oxidizing at 450 °C to 620°C in the presence of wire arc spray such as pure aluminium wire, pure zinc wire and etc.

We can apply thermal spray to small job in workshop like maintenance service up to huge project (on-site service) such as flare tower structure, pressure vessel, inner tank of electrical transformer, boiler tube and etc.